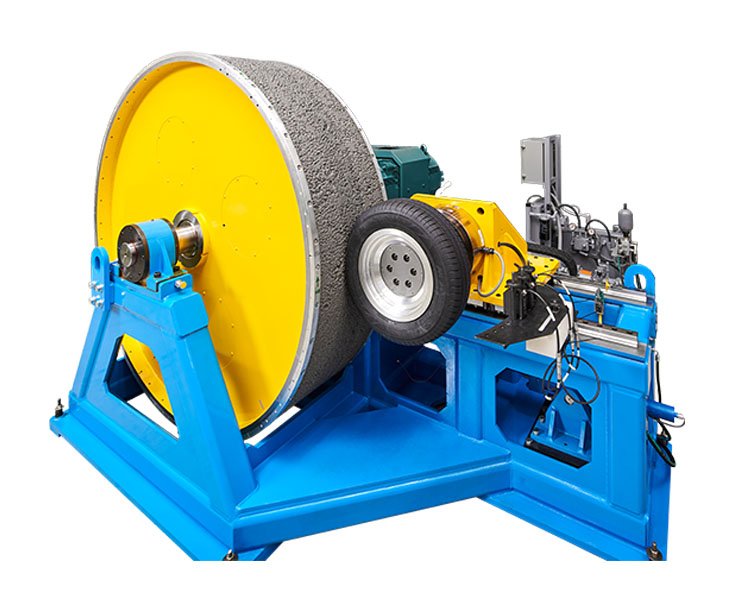

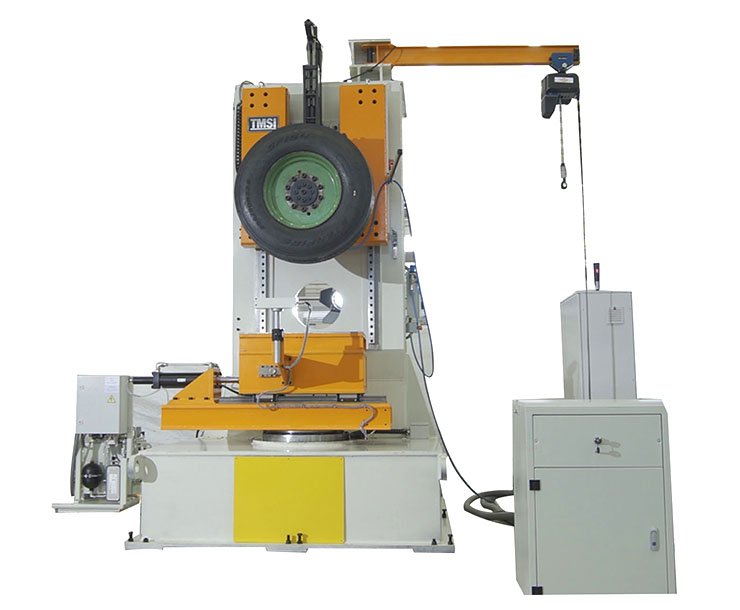

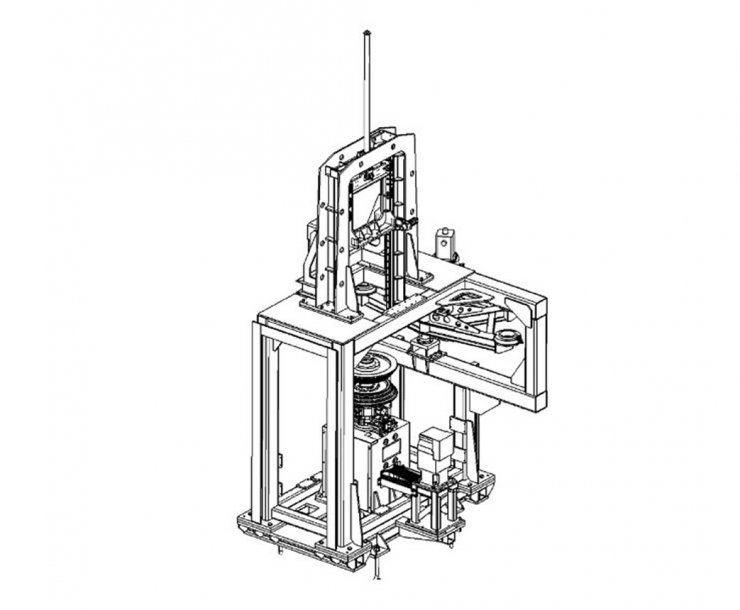

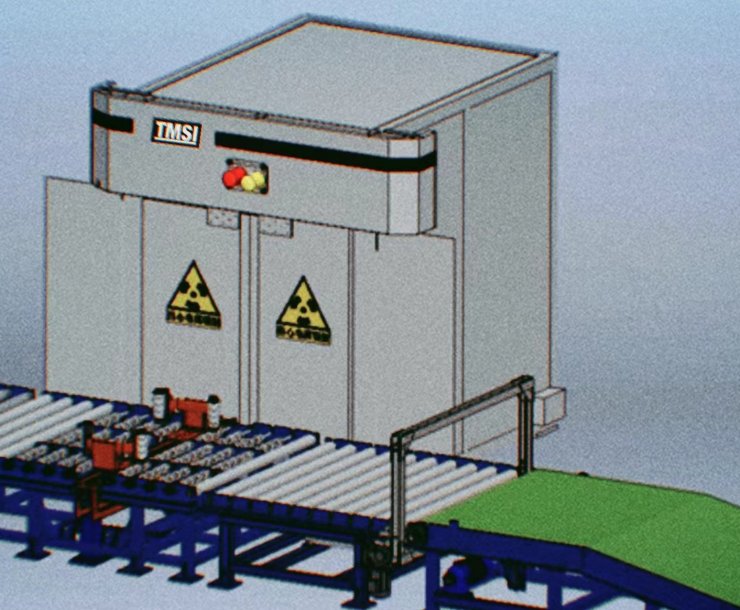

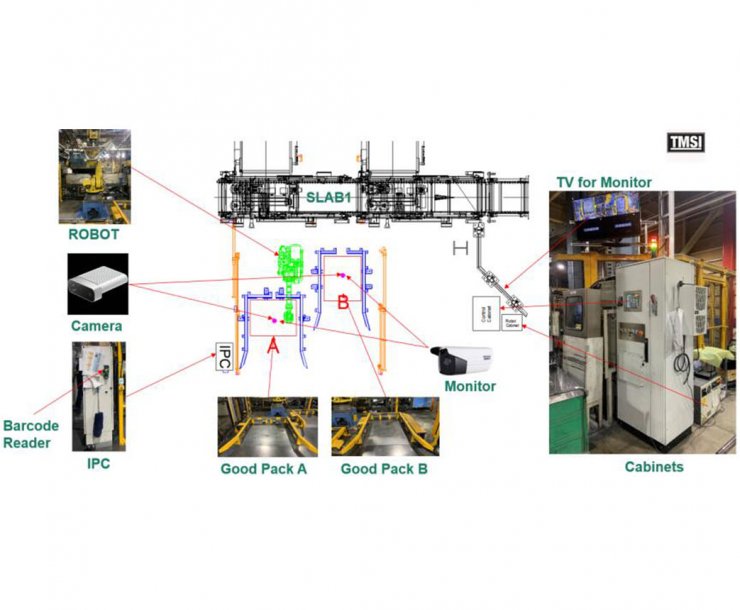

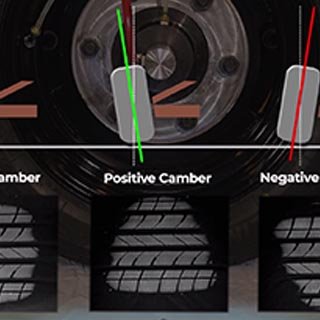

TMSI‘s Dynamic FootPrint Machine (DFPM) is comprised of a driven tire load carriage, a track, and a sturdy machine base. The machine’s overall size is up to 16.1m (length), 2.7m (width), and 4.2m (height). The tire is vertically loaded and can be subjected to drive/braking torques and various slip and camber angles. During the testing many of the tire’s dynamic properties will be measured and analyzed through our hardware and software systems. As an added feature, the tire’s tread motion relative to the road surface can be recorded and observed as the tire rolls over a glass plate.

With the capability of performing multiple tests with a single mounting, the DFPM significantly reduces testing costs, manpower, and capital equipment expenditures.

High Quality Tire Measurements

Camber Thrust CRAT | PRAT – Low Speed Steady State |

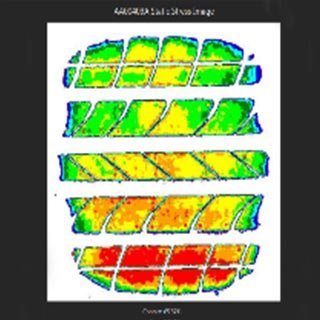

Footprint (photo) – Dynamic | Radial Stiffness |

Footprint (photo) – Static | Rolling Contact - probes |

Footprint Displacement (x, y probes) | Steady State Force and Moment |

Footprint Stress (x, y, z force probes) | Torsional Stiffness |

Lateral Stiffness | Mu-Slip Test |

Longitudinal Stiffness | Low Speed Uniformity |