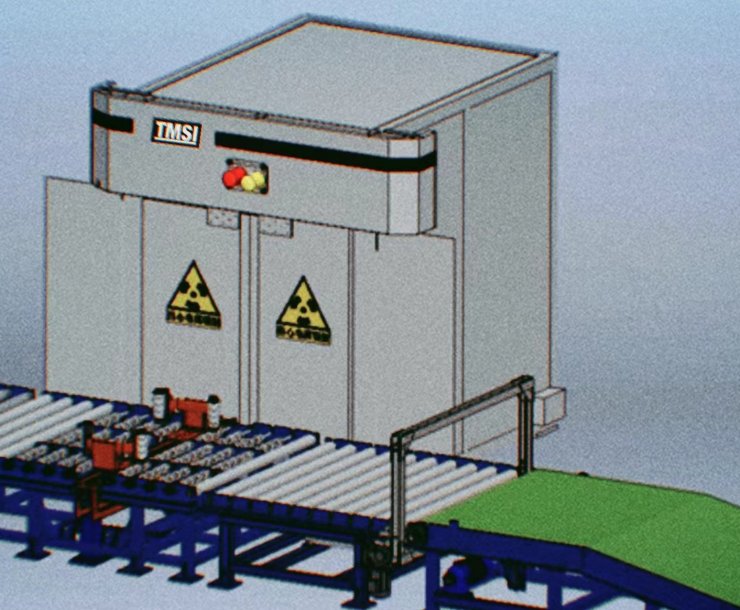

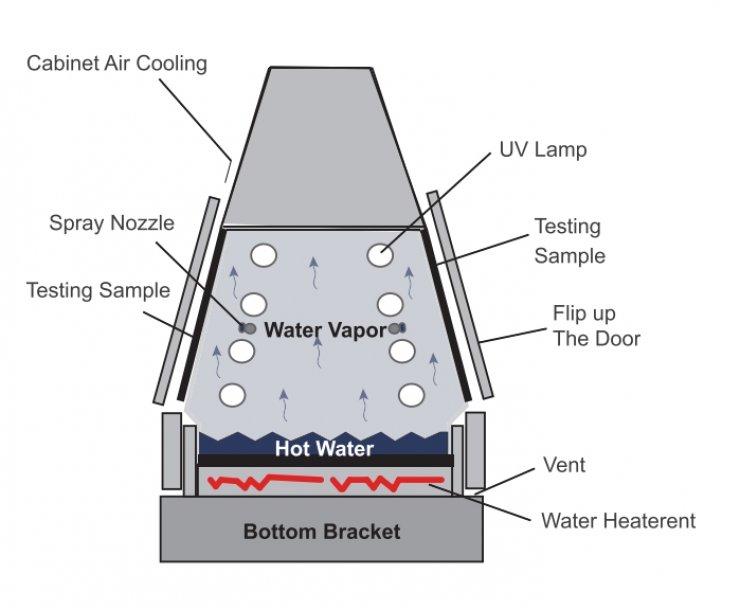

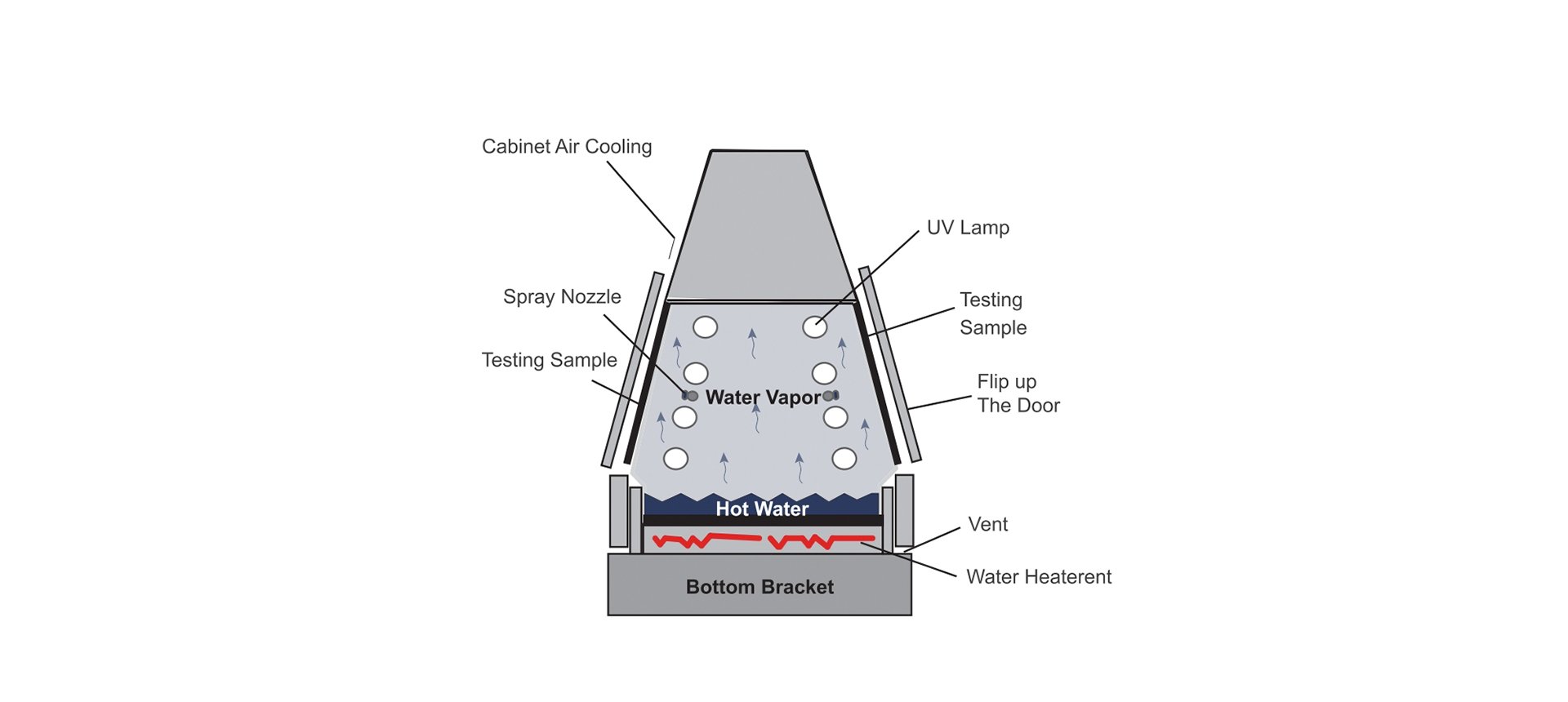

Condensation

In many outdoor environments,materials can be wet for up to 12 hours per day.Research has shown that dew,not rain,is the main contributor to this outdoor wetness.Simulate outdoor moisture erosion with a uniquecondensation feature.In the condensation cycle,water vapor is generated by heating the water tank at the bottomof the test machine.Hot water vapor keeps the chamber at 100%relative humidity at higher temperatures.

In the design of the tower UV aging chamber,the sample actually constitutes the side wall of the chamber,andthe back of the sample is exposed to the air in the laboratory room.The cooling effect of the room air causes thesurface temperature of the sample to be several degrees lower than that of the water vapour,thus ensuring thatthe water vapour will continue to condense on the sample surface.This condensed water is very stable puredistilled water.Even if ordinary tap water is used,pure water is collected on the surface of the sample.

Real Simulation

Dew,not rain,is responsible for most of the humidity in outdoor exposures.